机械设计的基本原理10.36

Dynamic Seals1

运动密封

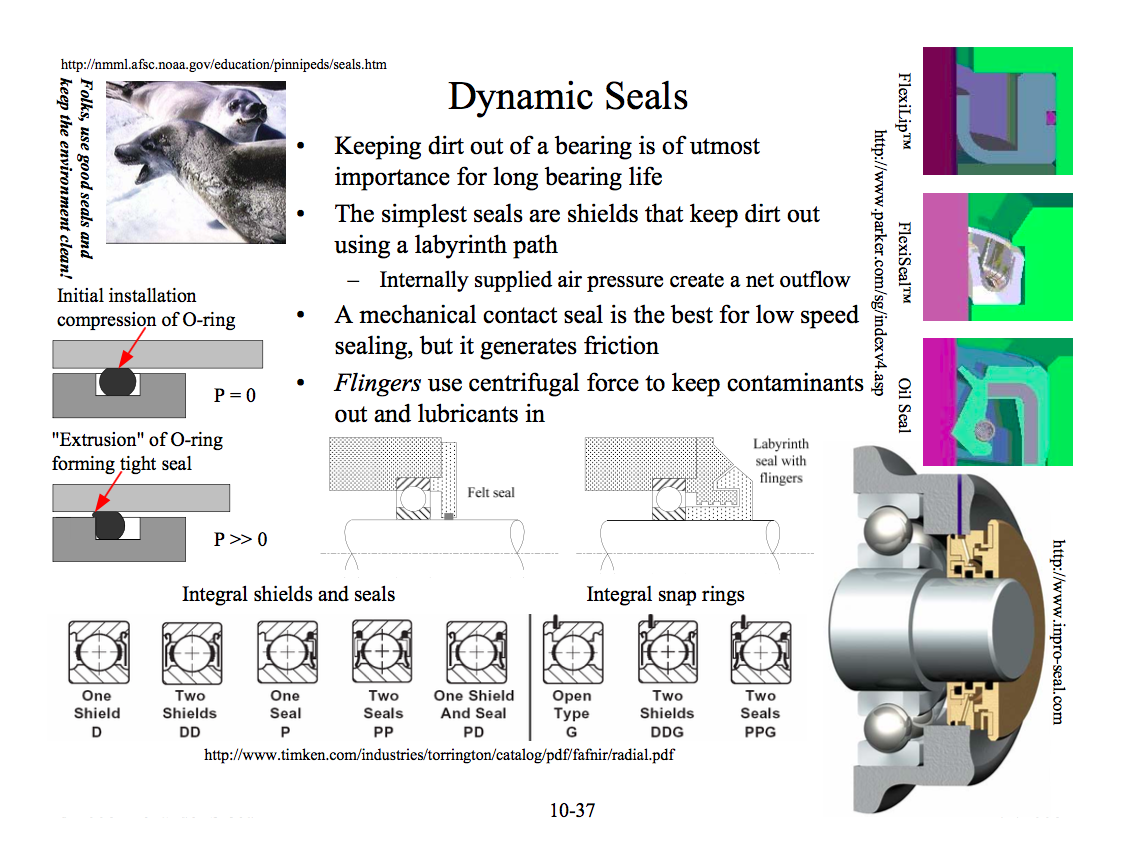

The job of a dynamic seal is to keep lubricant in and foreign material out while a shaft rotates and/or translates2. Indeed, the most impressive bearing with the biggest load capacity can rapidly be destroyed by the introduction of just a little bit of dirt. There are two primary methods of protecting bearings: seals or shields integral with the bearing, and external seals or shields. Bearings with integral seals or shields offer basic protection and take up little space as shown, and are commonly found in many consumer products and industrial machines used in non-aggressive environments.

运动密封的任务是保持润滑油不流出,不让赃物进入,此时轴还可以保持转动或者直线运动。事实上,最好的轴承在负载最大时,哪怕一点赃物都可以损坏整个轴承。有两种主要保护轴承的办法:密封或者有挡圈的轴承以及外部密封或者挡圈。整体密封和有挡圈的轴承是基本的保护,只需要很少的空间,很多消费产品和工业机床在不恶略的情况下都可以使用。

Contact-type seals make mechanical contact with the haft, and are used for both rotary and linear motion sealing. All contact-type dynamic seals generate heat, and thus they have speed limits on the order of 15-20 m/s. Noncontact type seals are used for high speed rotary motion applications, and use a labyrinth to create a long resistance path for foreign matter to follow before it can get to the bearing. By applying slight air pressure inside the bearing region, a small steady flow of air out of the bearing through the labyrinth further helps to keep out foreign material.

接触类密封圈与轴机械接触,直线和转动轴承都有使用。所有动态密封圈都会产生热量,所以其速度限制大概在15-20m/s.非接触类密封用在高速转动场合,采用迷宫密封可以通过很长的密封路径防止杂物进入。当在轴承内部施加稍许气压,很小的流出气压就可以帮助迷宫密封圈把异物排出。

One of the most common forms of contact-type seals is the simple “O” ring. Recall that O-rings are relatively stiff and are primarily designed to seal against high pressures by using the principle of self-help: as the pressure is increased, the O-ring is forced against the sealing surfaces, so they are not commonly used to seal bearings that run at high speeds.

最常见的接触类密封圈为O形圈。刚度相对大的o形圈,是通过自助定理来抵抗很高压力的:随着压力的提高,o形圈被抵在密封表面上,所以o形圈不常用在高速运转的轴承上。

The simplest and most common contact-type seal used for sealing bearings is a simple felt seal. A lip seal, or U-cup seal uses a compliant rubber lip to contact the shaft, where the elasticity of the rubber keeps it in contact, but with low force. A coiled spring behind the lip creates an energized lip seal with better control of the contact pressure. The use of the spring allows a harder sealing material, such as PTFE (Teflon) to be used, which enables such seals to operate from high vacuum to hundreds of atmospheres pressure.

最简单也是最常见的接触类密封圈是毛毡密封圈。唇形或者U形密封圈采用柔性橡胶来接触轴,橡胶的弹性保证一直接触,而且接触力很小。唇形后面的弹簧可以保证接触压力的大小在控制范围内,使得密封材料可以更硬一点,比如PTFE可以采用,使得密封圈可以在很高的真空度或者几百个大气压情况下工作。

Rotary motion of a shaft can act like a screw to pump foreign matter into the bearing. This effect can be reversed by placing small vane-like features on the surface of contact seals to have the effect of auguring out foreign matter. This principle of self-help extends to the use of shapes that act to fling materials off a rotating shaft, or to fling lubricant back into the bearing. Flingers are thus commonly used to help seal bearings used in wet environments.

轴的转动类似螺旋一样可以把异物带入轴承,这个效果可以通过在接触密封圈上增加小的风口类特征来逆转,从而把异物排出。这种自助原理可以推广到采用可以把材料排出轴或者把润滑油吸回轴承的形状。润滑油挡圈就是采用这个原理帮助轴承在潮湿环境中工作,实现密封的。

For linear motion applications, wiper-type seals work effectively to keep foreign matter out. Some will always get in, however, and then it is only a matter of time to failure. In severe environments, a scraper can act like a plow to remove most of the debris from the rail. The wiper then does a final cleaning and it also seals in the lubricant.

对于直线运动,刮片类的密封可以有效把异物排出。但是,还是有些会进入,所以只是失效的时间长短而已。在严重情况下,刮片会想耙子一样把异物移除,刮片上的毛会进行清洁,密封润滑油。

Seals are often almost an afterthought to many designers, yet they are the first line of defense for protecting bearings. Because they are not themselves structural members and do not support loads, they are often relatively delicate compared to the bearings and structures they protect. It is thus important to design the structure that supports the bearing to also support and protect the seal. If a seal is impacted, its structure may bend and contact the shaft with greater than intended force which can cause excessive heat and seal failure. Many a spindle has failed when shaft deflections increase rotating seal pressure which generates excessive heat that causes the seal’s elastomer to fail.

设计者通常最后才想到密封圈,但却是保护轴承的第一道防线。因为其本身不是结构件,不承受负载,所以其相对于其它保护的轴承和结构其本身更脆弱。所以,设计可以支持轴承并且支撑和保护密封圈的结构非常重要。如果密封圈会承受冲击,其结构会弯曲,与轴接触会产生更大的力造成过热和密封圈损坏。很多主轴的失效都是因为轴的变形增加了转动密封压力,产生过热造成密封圈的弹性体失效。

One common form of seal failure is from pressurized air or water that is used to clean off equipment. The pressurized fluid will push dirt and water through a seal and into the bearings. High pressure washers used to clean off engines may have caused far more harm than ever imagined. A shiny clean engine on the outside may have its bearings loaded with water and grit forced pass its seals!

常见的密封圈失效是因为清洁设备的压力气体或者流体造成的。压力流体可以把赃物和水推过密封圈,进入轴承。高压水用来清洁发动机,可能会造成无法想象的损坏。发动机表面看起来很干净,可能导致轴承上带水,颗粒会进入密封圈。

Fortunately, there are many seal companies with many different types of seals just waiting to help. Just remember to consider seals near the beginning of the design phase!

幸运的是,有很多密封圈公司有很多种不同的密封圈类型,只需要你来选型就好。记住,在设计初期就要考虑密封。

For your robot contest machine, what are the primary sources of contaminants that could harm the bearings? How can you most easily protect the bearings? Are external seals really necessary, or can simple shielded bearings work? When should you select a sealed bearing? Will the extra friction torque of the seals too unacceptably affect your power budget?

对于机器人比赛,那些污染物最影响轴承的寿命?你如何最简单的实现轴承的保护?外密封圈肯定有效,还是简单的罩子就可以?什么时候选择有密封的轴承?密封圈的额外扭矩是否会造成过热,使得你的功率预算大受影响?

1. Also see page 7-28 for a discussion of seals in the context of hydraulic and pneumatic systems

2.t has been said jokingly that fish do not have propellers so as to minimize the potential for problems with seals!