机械设计的基本原理10.19

Preload: Rolling Elements

预紧:滚动元件

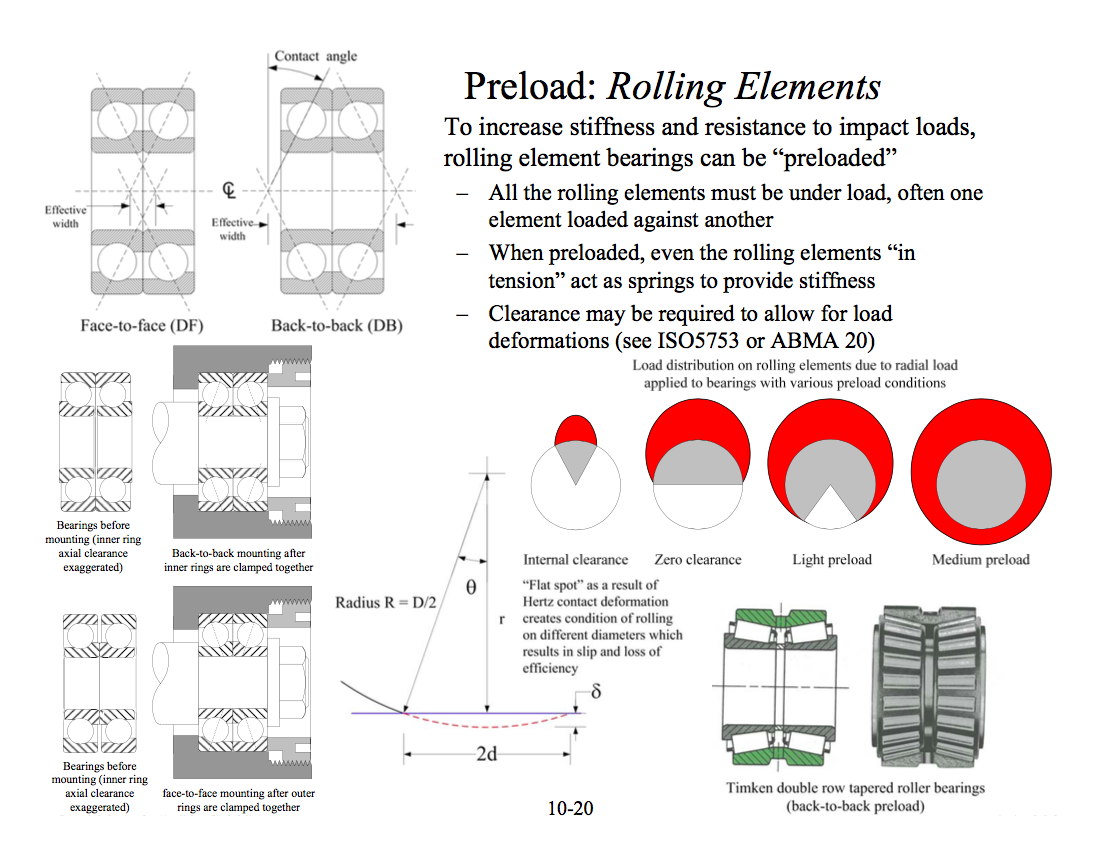

Rolling element bearings need to eliminate internal clearance, sometimes referred to as backlash, in order to increase the accuracy, stiffness and shock load capacity of the bearing. However, preload also causes the rolling elements to flatten slightly and thus effectively roll on different diameters. This shears the lubricating fluid and generates heat. For a rolling element diameter D and Hertzian contact zone of width d, the amount of slip can be estimated from:

滚动轴承需要消除内部间隙,有时候叫做背隙,这样就可以提高准确度、刚度和轴承的冲击负载能力。但是,预紧力也会造成滚动元件稍微变平,这样就可以在不同的直径上滚动。滚动会剪切润滑油,产生热量。如果滚动元件直径为D,赫兹接触区域宽度为d,那么滑动量可以估计为:

With the Hertz contact equations on page 9-12, assume a circular zone where c = d, to show that the radius of the contact zone is proportional to the contact pressure. Operating at a preload level that is a substantial proportion of the maximum load capacity generates excessive heat by differential slip. Fortunately, it only takes a little preload to achieve good performance:

通过9-12页的赫兹接触应力公式,假设圆形区域c=d,可以看出接触区域半径和接触压力成正比。如果轴承的预紧力和最大负载很接近,那么滑动就会产生非常严重的发热现象。幸好,只需要很少的预紧力可以满足很好的性能:

• Heavy preload is typically 5% of the maximum bearing load and is used when the system is subject to heavy shock loads. These bearings are not to be run at high speeds because heat generation will be fairly high.

高预紧力大概是轴承最大负载的5%,在系统承受高的振动载荷时使用。这种轴承不能高速转动,因为产生的热量会非常高。

• Medium preload is typically about 3% of the maximum bearing load and is used when the system is subject to moderate shock loads.

中等预紧力为轴承最大负载的3%左右,在系统承受中等冲击载荷时使用。

• Light preload is typically about 1% of the maximum bearing load and is used when the system is only lightly loaded, but it is to be run at its maximum speed for extended periods.

轻预紧力是轴承最大负载的1%左右,在负载很小的时候使用,但是能以最大速度转动很长时间。

• Clearance is specified for low cost bearings or for bearings which are known to be mounted where misalignment is likely to be encountered. However, bearings with clearance are easily damaged by shock loads.

间隙对于低成本轴承很常见,或者是安装轴承有对齐误差的情况。但是,轴承间隙很容易被冲击力破坏。

Preload fully loads all the rolling elements so that they have a finite Hertzian contact zone and thus provide stiffness and resistance to load from all the rolling elements. A thin film of lubricant in the Hertzian contact zones helps to act like a damper and prevent damage to the bearing. A bearing without preload only has one rolling element in contact, and an impact load causes the very small wedge of fluid directly beneath the contact point to be driven into the raceway like a penetrating projectile.

预紧使得滚动轴承完全承载,这样其赫兹接触区域有限,从而提供刚度和阻抗来保证所有元件承载。润滑油膜在赫兹接触区域产生阻尼作用,防止轴承破坏。没有预紧的轴承只有一个滚动元件接触,冲击力会使得接触点下面很小的润滑油契像穿透的炮弹一样进入凹槽内。

Bearings can either be preloaded with the use of oversize rolling elements, by forcing one bearing against another, or by forcing radial expansion or contraction of the inner or outer races respectively. Deep groove bearings, four-point contact bearings, double-row, and self-aligning bearings are most often preloaded with the use of oversize rolling elements.

可以通过更大尺寸的滚动元件来预紧轴承,或者通过轴承的相互作用力,或者通过内外圈径向的收缩或者膨胀来实现预紧。深沟球轴承、四点接触轴承、双列轴承和调心轴承是常用的预紧轴承,都采用过大尺寸元件来实现预紧。

Angular contact and tapered roller bearings are manufactured with axial offsets between the inner and outer races. A pair are then preloaded by forcing them axially together so there is no axial clearance between the outer or inner races. When the outer rings are forced together, a face-to-face mounting is achieved. The lines of force all intersect at the center of the system, which means that there is one instant center of rotation and that the bearing set has essentially no moment resistance. This makes this combination particularly well-suited where there might be some misalignment between sets of bearings. On the other hand, imagine what happens when the bearings get hot. The inner ring gets hot faster because the outer ring has a big housing in which to dissipate heat. Axial and radial expansion of the inner rings causes balls to be compressed. This bearing mounting is thermally unstable at high speeds.

角接触和锥形滚子轴承通过内外圈的轴向偏置来制造。通过一对轴承互相轴向盯顶紧来预紧,保证内外圈没有轴向间隙。当外圈通过外力贴紧,就形成了面对面安装。力的作用线在系统的中心交叉,这意味着系统只有一个瞬时转动中心,也就是说轴承没有抗弯矩能力。这使得该种设计最适合用于有对齐误差的地方。另一方面,想象下轴承发热后的情形,内圈比外圈热的更快,因为外圈有很大的外壳消散热量。内圈的轴向和径向膨胀造成钢球被压缩,所以这种配置的轴承高速时是热不稳定的。

Applying reciprocity, if the bearings are mounted so the inner rings are forced together to preload the bearings, then a back-to-back mounting is achieved. Here the instant centers are located outside the bearings and they can support large moments. On the other hand, they are sensitive to misalignment when pairs of sets are used to support a shaft. Now imagine what happens when they get hot: The compression of the balls caused by the shaft and inner rings radially expanding is relieved by axial expansion. Hence the bearings are thermally stable and are referred to as a thermocentric design.

采用相互性原理,如果轴承安装时通过两对内圈并紧来预紧轴承,那么就实现了背对背安装。这时候,瞬时旋转中心在轴承外面,所以可以承受弯矩。另一方面,如果采用成对支撑轴承,其对对齐误差非常敏感。现在想象轴承发热的情况,轴和内圈的径向膨胀造成小球压缩,但是被轴向的膨胀缓解。因此,该轴承是热稳定的,也叫做热中心设计。

Cylindrical roller bearings are often preloaded by expanding or contracting the inner or outer rings respectively. This also means that a bearing can be inadvertently preloaded by pressing it into a bore or onto a shaft!

滚子轴承通常由内外圈的膨胀或者压缩来预紧。这也意味着轴承可以通过压入孔或者压入轴来预紧。

How are you using rolling element bearings in your machine, and will your bearings require you to preload them, or can you use bearings preloaded with negative internal clearance? What types of bearings do you have?

你如何在你的机器中采用滚动轴承,是否需要预紧,或者可以通过负的间隙来预紧?你有那种类型的轴承?